- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 4 Author: Site Editor Publish Time: 2024-05-28 Origin: Site

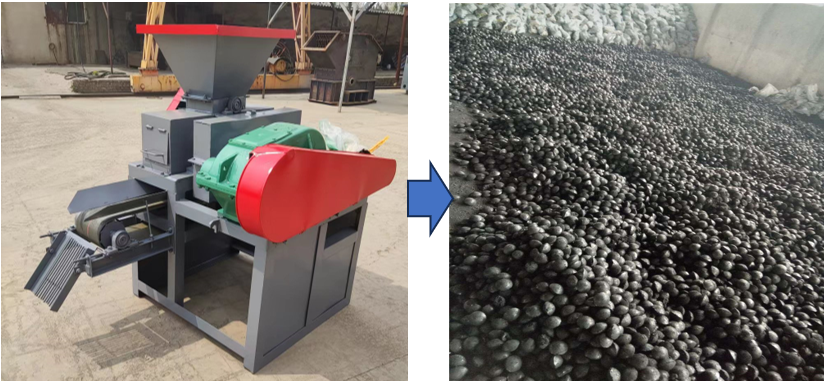

Ball briquette making machine is a commonly used machine for coal/charcoal ball manufacturers. Use coal powder/ charcoal powder and other raw materials to compress spherical carbon, which is used for heating, cooking, BBQ, etc.

What should you do when you want to produce carbon balls but don't know about this machine and don't have professional manufacturing experience?This article will first briefly introduce this ball press machine, so that you can understand its structure and machine working principle.

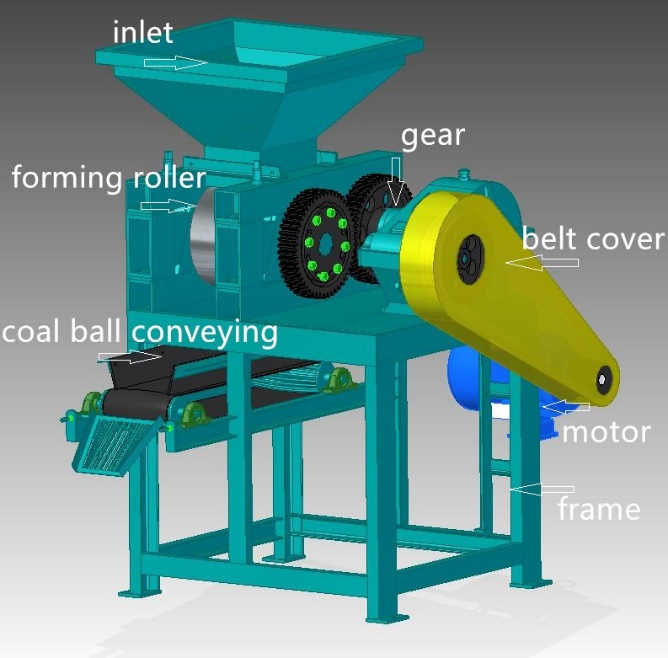

Firstly, understand the structure of the machine.

| This ball briquette maker mainly consists of the following parts: 1). Rolling bearing 2). Roll 3). V-belt 4). Coupling 5). Open gear 6). Discharge conveyor belt |

Then, understand the working principle of the ball press machine.

This series of ball presses have a main motor-through the V belt-to the reducer-the reducer through the coupling-to the main shaft-and then a pair of open The type gear ensures the synchronous movement of the two roller shafts (constant speed and opposite), and the driven roller is supported by the inclined block tensioning mechanism. The material enters the forming hopper evenly from the dosing equipment into the middle of the pair of rollers, and enters the ball-off state by rotating the ball at the same speed in the opposite direction of the roller.

Based on a preliminary understanding of the structure and working principle for the ball briquette making machine, we believe it can help you better develop in the field of carbon ball production.