- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 2 Author: Site Editor Publish Time: 2024-05-10 Origin: Site

In today's dynamic business landscape, selecting the right packing machine is crucial for efficient and streamlined packaging operations. Whether you are in the food industry, e-commerce sector, or any other field that requires packaging, finding a packing machine that suits your specific needs can significantly enhance productivity, reduce costs, and ensure customer satisfaction. This article aims to provide practical guidance on how to choose the packing machine that aligns with your requirements.

Begin by thoroughly analyzing your packaging requirements. Consider factors such as the type of products you need to pack, their size and shape, the desired packaging speed, and the volume of production. Understanding these elements will help you identify the most suitable packing machine for your specific needs.

There is a wide range of packing machines available, each designed for different packaging applications. Familiarize yourself with the following common types:

a. Pellet Packing Machines: In order to meet the needs of different customers, the equipment adopts two feeding methods: pneumatic and servo electric, the difference is that the packaging speed and the accuracy of a single package are different, and the servo motor feeding and packaging machine is equipped with a full touch screen weighing instrument to control the operation more simple and intelligent.

b. Powder Packing Machines: The system is applied to quantitative automatic weighing, filling, kneading, accumulating weigh and times, stitching and conveying with manual assistant for powder material in the flour factory and other industry.

It is suitable for quantitative packaging of powder in flour, powder industry, etc.

c. Belt Packing Machines: Belt quantitative packaging machine is designed for powdery granular mixture, poor fluidity of the material, the whole equipment surface treatment using paint process, and the structure is small, easy to install, simple to use. The system uses a unique anti-mechanical interference, anti-electromagnetic interference design, can work normally in harsh environments.

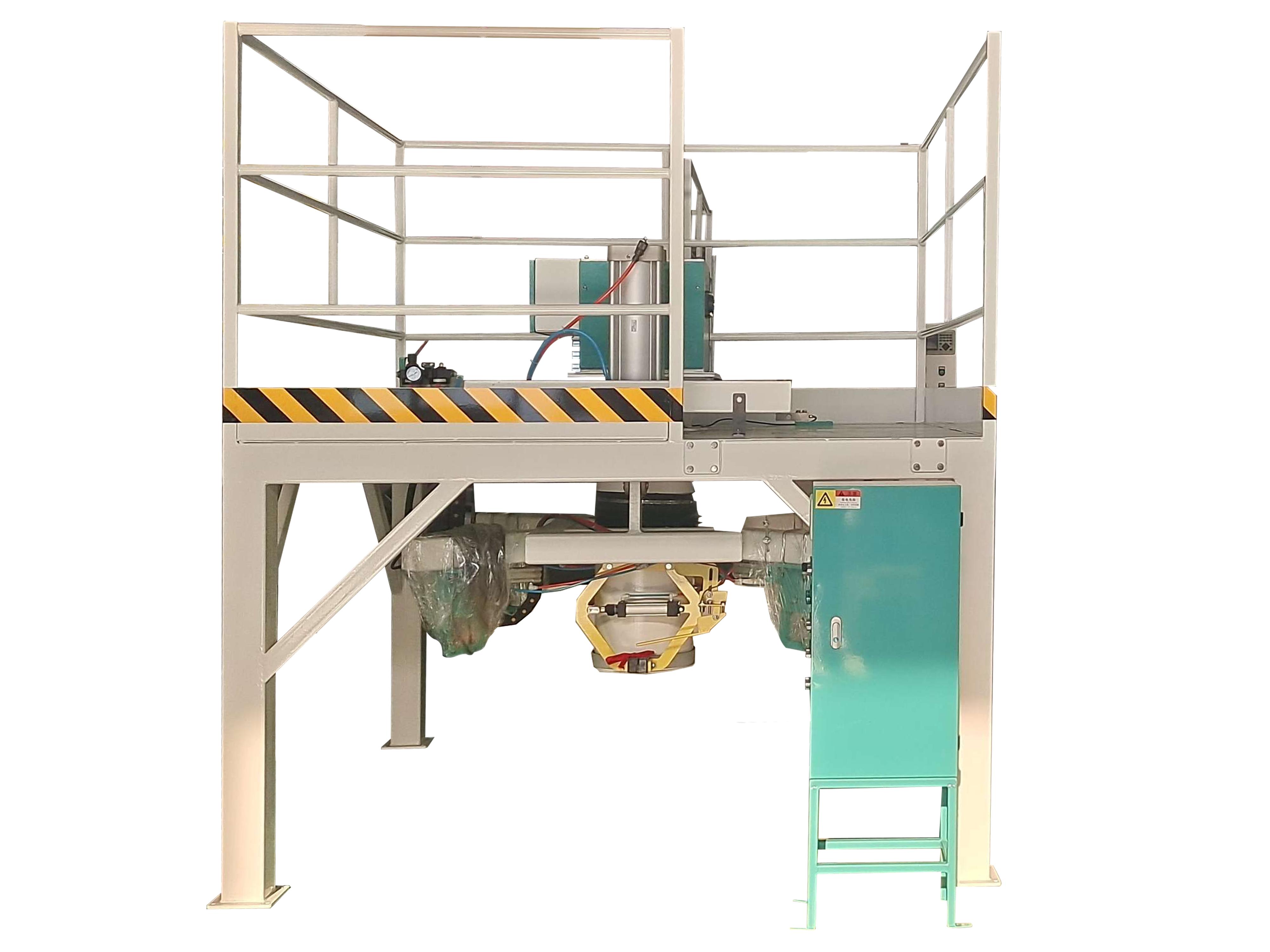

d. Ton Packing Machines: New controller with high precision, working stable, can display the total weight, number of package, easy operation.The adaptive software, having the function of over-weight warning and auto-diagnosis.Products using imported sensor, pneumatic actuator, easy maintenance and non-pollution.The main material body is carbon steel, with painted plastic. And material contact part is stainless iron, corrosion resistance, and long service life.

e. Food Pakcing Machines: Equipped with safety protection to meet enterprise safety management requirements.Using intelligent thermostat, the temperature control is accurate and the sealing is beautiful and smooth.Use PLC servo system, pneumatic control system and touch screen to form the drive control core, which maximizes the control accuracy, reliability and intelligence of the whole machine.The touch screen can store the packaging process parameters of a variety of different products.

Evaluate your production requirements and determine the desired packaging speed in terms of units per minute or per hour. It is crucial to choose a packing machine that can handle your required output capacity without compromising quality. Look for machines with adjustable speed settings to accommodate different production demands.

Consider the packaging materials you plan to use, such as woven bags, plastic bags, sealed bags, etc. Make sure the packaging machine you choose is compatible with your preferred materials. Verify the machine's ability to handle packaging materials of different thicknesses, sizes and properties to avoid any compatibility issues.

Automation plays a vital role in enhancing packaging efficiency and reducing labor costs. Determine the level of automation you require for your packaging process. Some machines offer advanced features like automatic feeding, filling, sealing, and labeling, while others may require manual assistance. Additionally, consider the compatibility of the packing machine with your existing production line and whether it can integrate seamlessly into your workflow.

Investing in a high-quality packing machine is essential for long-term performance and reliability. Research reputable manufacturers or suppliers known for producing durable and efficient equipment. Check customer reviews and testimonials to gauge the overall satisfaction and reliability of the machines.

Consider the maintenance requirements of the packing machine. Look for equipment that is easy to maintain, with readily available spare parts and technical support. Regular maintenance and reliable customer support can significantly minimize downtime and ensure smooth operations.

While cost is an important factor, it should not be the sole determinant of your decision. Consider the long-term benefits and return on investment that the packing machine offers. A higher-quality machine may have a higher upfront cost but can provide significant cost savings through increased efficiency, reduced material waste, and minimized downtime.

Choosing the right packing machine is a critical decision that can have a substantial impact on your packaging operations. By analyzing your packaging requirements, understanding the available machine types, considering speed and output capacity, assessing material compatibility, evaluating automation and integration capabilities, prioritizing quality and reliability, considering maintenance and support, and aligning your budget, you can make an informed choice that suits your specific needs. Take the time to research different suppliers, seek expert advice when necessary, and invest in a packing machine that will contribute to the success and growth of your business.