- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 13 Author: Site Editor Publish Time: 2024-06-05 Origin: Site

In the world of biomass processing and feed production, the terms "wood pellet machine" and "feed pellet machine" are often used interchangeably, leading to confusion and misconceptions. While these two types of machines may share some similarities, they have distinct features, applications, and operational requirements. This article aims to shed light on the key differences between wood pellet machines and feed pellet machines, empowering readers to make informed decisions when investing in these important pieces of equipment.

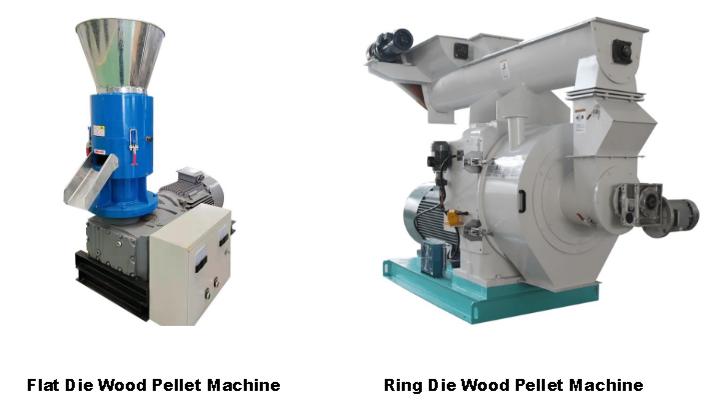

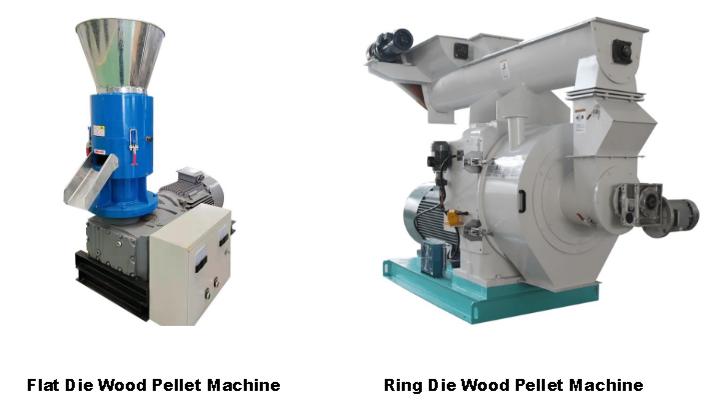

Wood pellet machines are primarily designed for the production of wood pellets, which are a popular and eco-friendly fuel source used for heating, power generation, and industrial applications. These machines are engineered to process various types of woody biomass, such as sawdust, wood shavings, and forestry residues, into high-density, uniform pellets.

Specialized Feedstock: Wood pellet machines are optimized to handle the unique properties and composition of woody biomass, ensuring consistent and efficient pellet production.

High-Pressure Compaction: The machine's internal mechanisms apply immense pressure to the feedstock, compacting it into dense, durable pellets that are suitable for long-distance transportation and storage.

Precise Moisture Control: Wood pellet machines are equipped with advanced moisture management systems to maintain the optimal moisture content of the final pellets, which is crucial for their combustion characteristics and handling.

Strict Quality Standards: Wood pellet machines are designed to produce pellets that meet industry-specific quality standards, ensuring consistent performance and compliance with environmental regulations.

Feed pellet machines, on the other hand, are primarily used in the livestock and aquaculture industries to produce high-quality animal feed pellets. These machines are engineered to handle a wide range of organic feedstocks, including grains, oilseeds, and various by-products from the agricultural and food processing sectors.

Versatile Feedstock: Feed pellet machines are capable of processing a diverse array of organic materials, allowing for the formulation of customized feed blends to meet the specific nutritional requirements of different animal species.

Nutritional Preservation: The pelletizing process in feed pellet machines is designed to preserve the nutritional value and palatability of the feed, ensuring optimal animal health and performance.

Improved Handling and Storage: Feed pellets produced by these machines are more compact, durable, and resistant to spoilage, facilitating efficient storage and transportation.

Compliance with Feed Safety Regulations: Feed pellet machines are designed to meet stringent food safety standards and regulations, ensuring the production of safe and wholesome animal feed.

Feedstock Composition: Wood pellet machines are specialized for processing woody biomass, while feed pellet machines can handle a broader range of organic materials, including grains, oilseeds, and agricultural by-products.

End-Use Application: Wood pellets are primarily used as a fuel source, while feed pellets are designed for animal consumption and nutrition.

Operational Requirements: Wood pellet machines often require more specialized maintenance and quality control measures to ensure consistent pellet properties, while feed pellet machines may have additional considerations related to feed safety and nutritional integrity.

Market Dynamics: The demand and pricing for wood pellets and animal feed pellets are influenced by different market factors, such as energy policies, commodity prices, and agricultural trends.

Understanding the distinct differences between wood pellet machines and feed pellet machines is crucial for businesses and individuals seeking to invest in these important pieces of equipment. By recognizing the unique features, applications, and operational requirements of each machine type, customers can make informed decisions that align with their specific needs, whether it's for biomass processing or animal feed production. This knowledge can help ensure the successful implementation and long-term performance of these critical technologies, ultimately contributing to a more sustainable and efficient future.