- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 15 Author: Site Editor Publish Time: 2024-05-31 Origin: Site

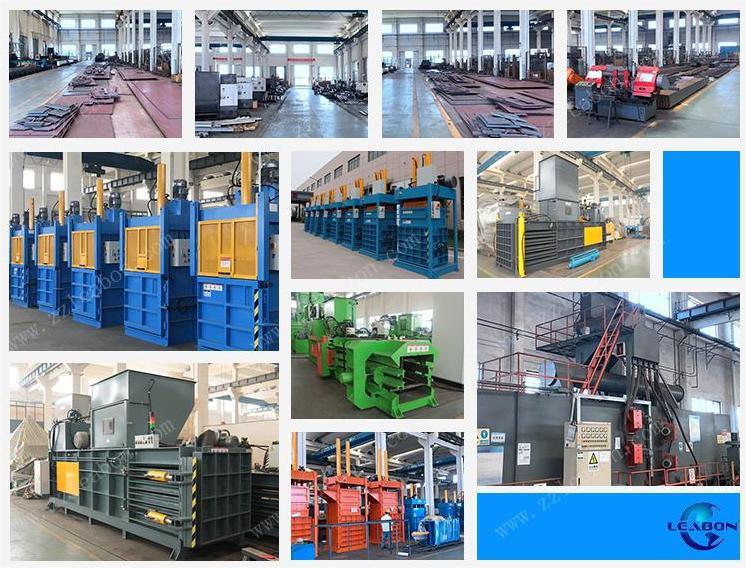

In the world of waste management and recycling, the choice of hydraulic baler orientation can have a significant impact on efficiency, productivity, and overall performance. As businesses and municipalities seek to optimize their recycling operations, understanding the key differences between vertical and horizontal hydraulic recycling balers is increasingly important. This article takes an in-depth look at the unique features, benefits, and applications of these two baler configurations.

Vertical hydraulic recycling balers use gravity to facilitate the loading process, making them ideal for handling bulky or lightweight materials such as cardboard, paper, and plastics.

1)Smaller Footprint: Vertical balers typically have a more compact design that takes up less floor space than horizontal balers. This makes them ideal for facilities with limited available space.

2)Easier Material Loading: Vertical balers make material feeding simpler and more ergonomic, reducing physical strain on the operator.

3)Efficient Compaction: Downward gravity combined with hydraulic compression produces highly dense and consistent bales for optimized storage and transportation.

Horizontal hydraulic recycling balers feature a side-loading design where material is fed into the machine from the side. This configuration is often useful for handling heavier or bulkier materials, such as scrap metals, textiles, and dense plastics.

1)Higher Throughput: Horizontal balers can typically process larger volumes of material at a faster rate, making them ideal for high-volume recycling operations.

2)Increased Bale Size: Horizontal balers can produce larger bales, which is beneficial for shipping and storage, especially for dense materials.

3)Material Handling Versatility: The side-loading design of horizontal balers allows for more flexibility in material handling, accommodating a wider range of recyclables.

1)Material Characteristics: The type, size, and density of recyclable material should be the primary considerations when choosing between vertical and horizontal balers.

2)Facility Layout and Space Constraints: Available floor space, overhead clearance, and material flow within a facility can influence the choice between vertical and horizontal balers.

3)Throughput and Production Needs: The required handling capacity and production volume will determine the appropriate baler configuration to meet the needs of the operation.

4)Cost Considerations: Both vertical and horizontal balers have different capital and operating costs that should be evaluated during the decision-making process.

The choice between vertical and horizontal hydraulic recycling balers is not a one-size-fits-all decision. It requires a careful evaluation of the recycling facility’s specific needs, material characteristics, and operational requirements. By understanding the unique benefits and applications of each baler configuration, businesses and municipalities can make informed decisions to optimize their recycling processes, improve efficiency, and contribute to a more sustainable future.