- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 8 Author: Site Editor Publish Time: 2024-04-18 Origin: Site

Wood flour (powder) mill is a common crushing equipment in daily production activities. How to properly start-up a new wood powder making machine to ensure better and more sustainable operation?

Horizontal wood powder mill Vertical wood powder mill

Firstly, it is important to understand the main structure of the machine.

1.The wood flour (powder) mill consists of 3 main parts: the main body, the middle body, and the lower body.

Horizontal wood powder mill Vertical wood powder mill

2. The crushing knife consists of 3 kinds of knives ----------7 types of knives, 1 type of knives, and a centrifugal knife.

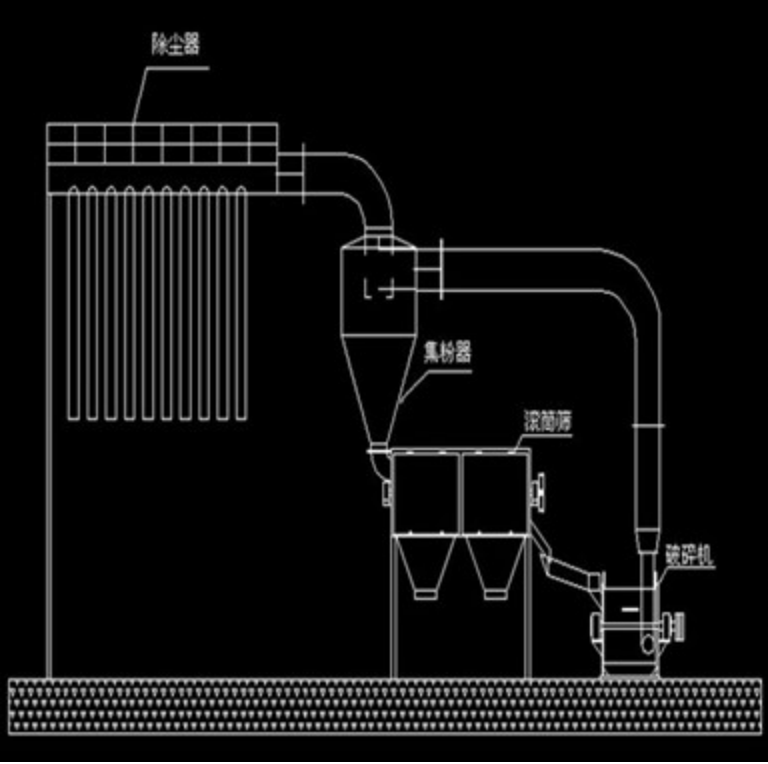

3. The feeder consists of a screening machine, a powder collector, and a dust collector.

4. The main crushing room adopts 7-type knives, 1-type knives, and centrifugal knives, which can be used for coarse crushing, fine crushing, and centrifugal crushing.

Then, follow the correct instructions to install the wood powder making machine.

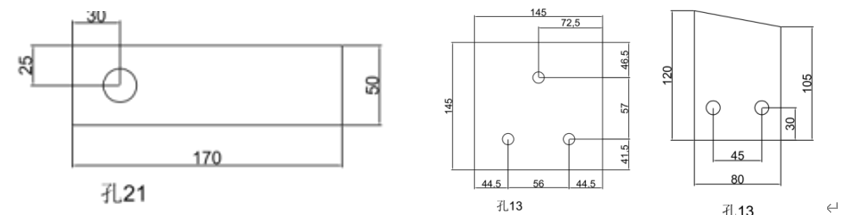

| When installing, you can refer to the installation diagram or the overall picture, and arrange it appropriately according to the situation of the factory. Place the host, motor, collector, sieve, bag filter, etc. according to the installation diagram, leave reserved holes in the bolt positions, and then place the host and hang the ground bolts. (Each part of the machine will be labeled and connected according to the number) |

Finally, the correct startup is necessary.

1. Before starting, it is necessary to strictly check the installation requirements of all parts of the machine. Metal objects should not fall into the machine. First, use your hands to move the belt for trial operation to see if there is any biting or rotating collision with the shell to avoid accidents.

2. When adding materials, they should be kept uniform, and the feeding particle size should be based on the hardness of the material. The diameter of hard materials should not exceed three centimeters, and metal hard blocks are strictly prohibited from entering the feeding port.

3. During use, the motor load should not be overloaded and should maintain normal operation.

4. The wear program of the blade and grinding plate should be checked regularly. If severe wear is found on the blade grinding plate, it should be replaced in a timely manner.

After starting up, using materials test several times, if there are no malfunctions, the machine can be used normally.