- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 1 Author: Site Editor Publish Time: 2024-01-12 Origin: Site

How to Correctly Install the Rollers on Pellet Machine

When we use a feed/wood pellet machine to produce pellets, in order to extend the using time of the feed pellet making machine, it usually needs to replace the spare part- rollers on the pellet machine after using a period of time.

However, how to correctly install the roller of the pellet machine troubles many customers.

Today, let's organize the installation method for the roller of the pellet machine.

First , prepare the following parts of rollers on pellet machine.

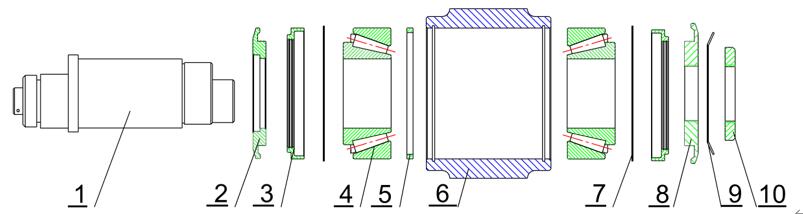

1, eccentric shaft 2, cover 3. Oil retaining ring (2 pcs)

4. Bearings (2 pairs) 5. Spacer 6. Pressure roller shell

7, inner circlip 8. Threaded cap 9. Non-return washer 10. Non-return nut

1-Press-fit spacer and bearing inner ring

1-1 Place the roller shell on the platform, and use the tooling to press the spacer to the center position; 1-2 Place the outer ring of the bearing as shown in the figure and press it to position; 1-3 When changing the surface, the outer ring of the bearing is also pressed; |

|

2, Install bearing outer ring and oil retaining ring

| 2-1 Insert the inner ring of the bearing, the oil baffle ring, and the pressure roller shell in turn; 2-2 Clamp the hole circlip into the circlip groove of the pressure roller; 2-3 Cover |

3, Press in the eccentric shaft

As shown in the figure, press in the eccentric shaft to make the step of the eccentric shaft and the cover tightly pressed; |

|

4, Press into the bearing at the other end

| 4-1 Turn the pressure roller upside down to the tooling platform; 4-2 Place the other half of the bearing inner ring on the eccentric shaft; 4-3 Press the bearing into place with a pressing sleeve. |

5, Install the other end cap

5-1 Install the oil baffle ring; 5-2 Use a tool to snap the circlip into the circlip groove; 5-3 Screw the threaded cover, and check that the bearing should not be dead.The pressure roller shell should be able to rotate easily in order to rotate it. |

|

This is picture of roller assembly. After all parts are installed in the above order, the complete pellet machine accessory - roller is shown in the picture