- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

loading

| Availability: | |

|---|---|

| Quantity: | |

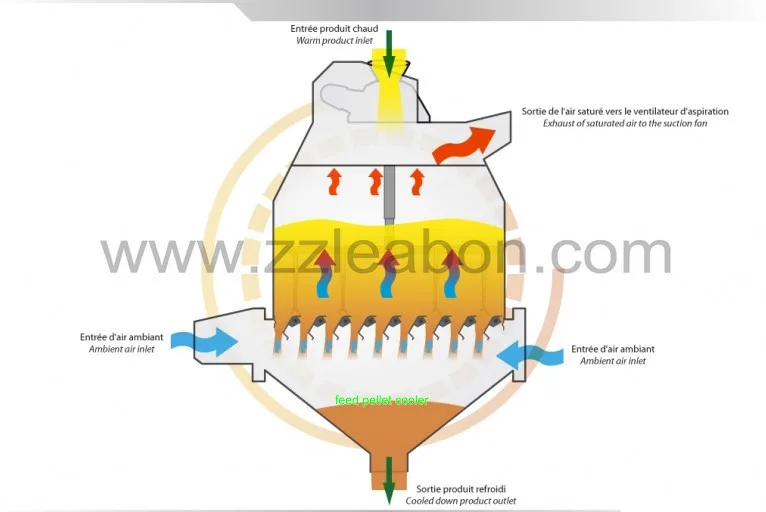

The counter flow cooler machine principle is adopted to cool the pellets with high temperature and moisture.

Hot air touches hot pellets and cool air touches cool pellets, so as to avoid the pellet surface cracking caused by sudden cooling produced by direct touching between cool air and hot pellets.

1.using the counterflow cooling principle on high temperature and humidity of the particles to cool the hot air in contact with

hot material, cold material in contact with the cold, cold and hot material to avoid direct contact with the surface of the

resulting particles produced quench cracking phenomenon;

2. increase the cooling capacity, the cooling time to extend the material, substantially improve the cooling effect;

3. using closed airlock feed inlet to eliminate the phenomenon of channeling the wind, the cooling effect is good;

4. features adjustable conical bulk material bodies, uniform cloth;

5. cooler top made of stainless steel, corrosion resistance, long life;

6. spool reciprocating mechanism nesting, nesting stable and reliable;

7. apply to any granular material cooling;

| Model Parameters | SKLN 1.5 | SKLN 2.5 | SKLN 4 | SKLN 6 | SKLN 8 | |

| Capacity (t/h) | 3 | 5 | 10 | 15 | 20 | |

| Cooling Time (min) | Not less than 10-15 | |||||

| Product Temp. after cooling | Not 3~5℃ higher than ambient temperature | |||||

| Air Absorbing Volume (m3/min﹒t) | 34 | |||||

| Cooling Volume(m3) | 1.5 | 2.5 | 5 | 7 | 8 | |

| Power (KW) | 1.1 | 1.1 | 1.5 | 1.5 | 2.2 | |

| Power of Airlock (KW) | 0.55 | 0.75 | 0.75 | 0.75 | 1.1 | |

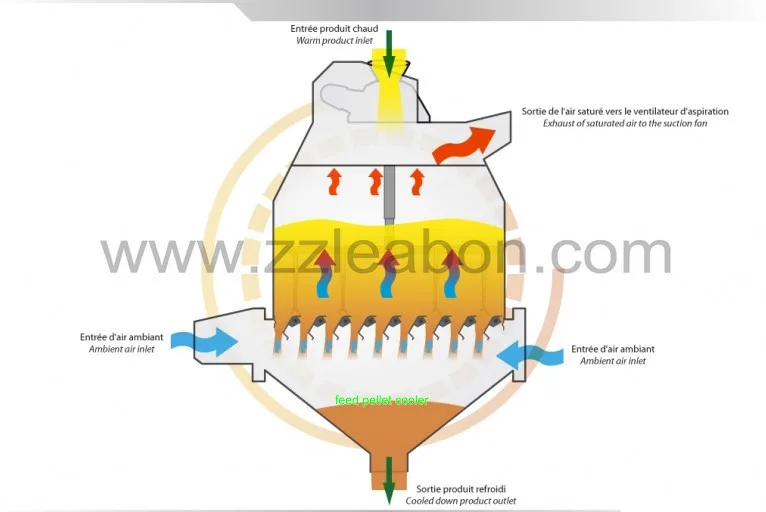

The counter flow cooler machine principle is adopted to cool the pellets with high temperature and moisture.

Hot air touches hot pellets and cool air touches cool pellets, so as to avoid the pellet surface cracking caused by sudden cooling produced by direct touching between cool air and hot pellets.

1.using the counterflow cooling principle on high temperature and humidity of the particles to cool the hot air in contact with

hot material, cold material in contact with the cold, cold and hot material to avoid direct contact with the surface of the

resulting particles produced quench cracking phenomenon;

2. increase the cooling capacity, the cooling time to extend the material, substantially improve the cooling effect;

3. using closed airlock feed inlet to eliminate the phenomenon of channeling the wind, the cooling effect is good;

4. features adjustable conical bulk material bodies, uniform cloth;

5. cooler top made of stainless steel, corrosion resistance, long life;

6. spool reciprocating mechanism nesting, nesting stable and reliable;

7. apply to any granular material cooling;

| Model Parameters | SKLN 1.5 | SKLN 2.5 | SKLN 4 | SKLN 6 | SKLN 8 | |

| Capacity (t/h) | 3 | 5 | 10 | 15 | 20 | |

| Cooling Time (min) | Not less than 10-15 | |||||

| Product Temp. after cooling | Not 3~5℃ higher than ambient temperature | |||||

| Air Absorbing Volume (m3/min﹒t) | 34 | |||||

| Cooling Volume(m3) | 1.5 | 2.5 | 5 | 7 | 8 | |

| Power (KW) | 1.1 | 1.1 | 1.5 | 1.5 | 2.2 | |

| Power of Airlock (KW) | 0.55 | 0.75 | 0.75 | 0.75 | 1.1 | |