- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

loading

| Availability: | |

|---|---|

PM- 350T

LEABON

8474802000

CE 100-400kgs/h PTO Wood Pelletizer for Sale

Introduction

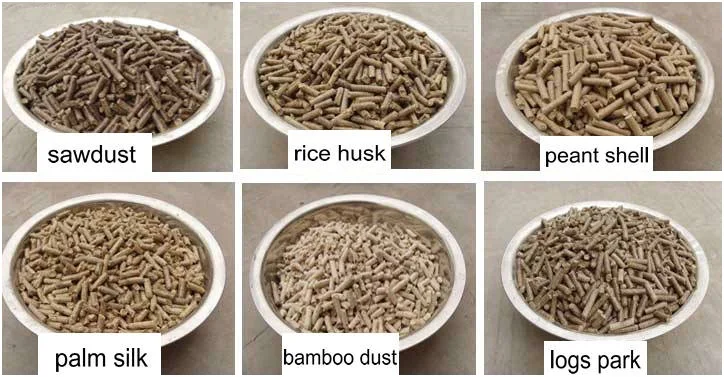

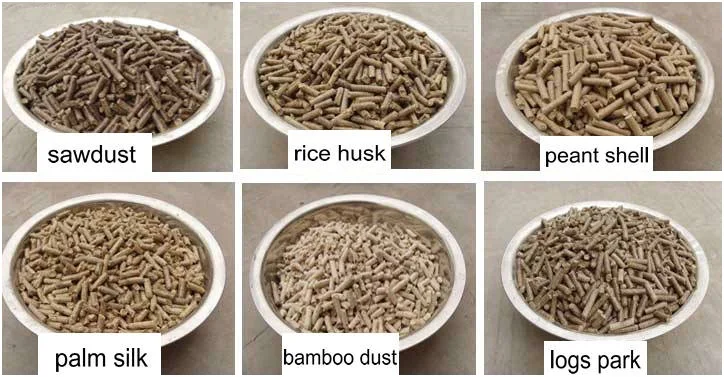

1. KAF series pellets mill ,wood pellets making machine /pellet press can press biomass particles such as sawdust, straw, rice husk and etc.

2. Use Cold-pressing molding technology, Polishing integer process. Streamline appearance, Compact structure.

3. High output, low consumption and noise, better stability and lower fault rates, Fatigue resistance is strong, continuous

production, economy and durability.

Main Data

| Model | Output (kg/h) | Pellet (mm) | Flat die diameter (mm) | Overall Dimension (mm) | Weight (kg) |

| PM- 200T | 100-150 | 6,8 | 200 | 450*400*1100 | 250 |

| PM- 250T | 200-250 | 6,8 | 250 | 550*450*1100 | 300 |

| PM- 300T | 250-300 | 6,8,10 | 300 | 600*550*1250 | 350 |

| PM- 350T | 350-400 | 6,8,10 | 350 | 650*600*1300 | 400 |

PS: tractor driven wood pellet machine are mainly used in the farm, and are connect with tractor to save diesel engine and electric motor.

Spare Parts : Flat Die + Roller

Final Wood Pellet As Fuel:

Package & Delivery :

CE 100-400kgs/h PTO Wood Pelletizer for Sale

Introduction

1. KAF series pellets mill ,wood pellets making machine /pellet press can press biomass particles such as sawdust, straw, rice husk and etc.

2. Use Cold-pressing molding technology, Polishing integer process. Streamline appearance, Compact structure.

3. High output, low consumption and noise, better stability and lower fault rates, Fatigue resistance is strong, continuous

production, economy and durability.

Main Data

| Model | Output (kg/h) | Pellet (mm) | Flat die diameter (mm) | Overall Dimension (mm) | Weight (kg) |

| PM- 200T | 100-150 | 6,8 | 200 | 450*400*1100 | 250 |

| PM- 250T | 200-250 | 6,8 | 250 | 550*450*1100 | 300 |

| PM- 300T | 250-300 | 6,8,10 | 300 | 600*550*1250 | 350 |

| PM- 350T | 350-400 | 6,8,10 | 350 | 650*600*1300 | 400 |

PS: tractor driven wood pellet machine are mainly used in the farm, and are connect with tractor to save diesel engine and electric motor.

Spare Parts : Flat Die + Roller

Final Wood Pellet As Fuel:

Package & Delivery :

| Model | Output (kg/h) | Pellet (mm) | Mould (mm) | Size (mm) | Weight (kg) |

| PM200T | 100-150 | 6-8 | 200 | 450*400*1100 | 250 |

| PM250T | 200-250 | 6-8 | 250 | 550*450*1100 | 300 |

| PM300T | 250-300 | 6-10 | 300 | 600*550*1250 | 350 |

| PM350T | 350-400 | 6-15 | 350 | 650*600*1300 | 400 |

| PM450T | 500-700 | 6-10 | 450 | 850*800*1450 | 800 |

| Model | Output (kg/h) | Pellet (mm) | Mould (mm) | Size (mm) | Weight (kg) |

| PM200T | 100-150 | 6-8 | 200 | 450*400*1100 | 250 |

| PM250T | 200-250 | 6-8 | 250 | 550*450*1100 | 300 |

| PM300T | 250-300 | 6-10 | 300 | 600*550*1250 | 350 |

| PM350T | 350-400 | 6-15 | 350 | 650*600*1300 | 400 |

| PM450T | 500-700 | 6-10 | 450 | 850*800*1450 | 800 |