- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

loading

LH-420

LEABON

8479820090

4-10T/H wood pellet making line

Product Description

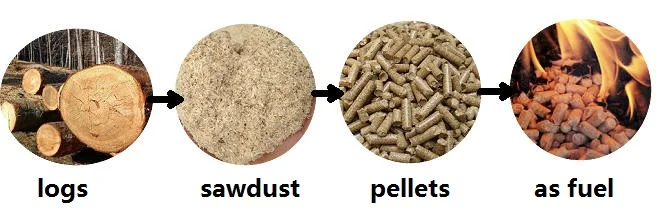

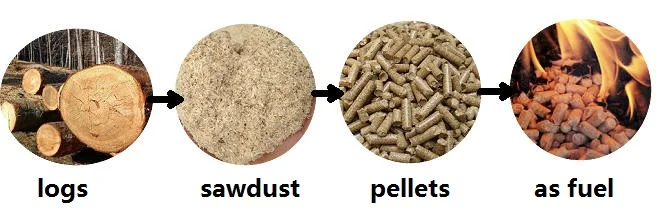

Production Flow Chart of Complete Wood Pellet Line:

Wood Chipping --- Sawdust Grinding ---- Drying ---- Pelletizing --- Cooling & Screening ---- Packing

| Introduction | Complete wood pellet line is the process of making waste materials into solid fuel. The objects are used for burning purposes. |

| Raw materials | Logs,Spruce, Pine, Birch, Oak ,Acacia etc Wood , Sawmill Waste Wood Planks, Furniture Factory Waste Wood, Sawdust, Bamboo, EFB, Nuts Shell etc. |

| Moisture and Size | 3-5mm; 10-15% moisture content |

| Diameter of wood pellets | 6/8/10/12mm |

Detailed Images

1. Wood Cutting Process : Chainsaw split big diameter wood into smaller one at first.

2. Wood Chipping Process: Wood Chipper Process Small Size Wood Into Wodd Chips.

3. Wood Sawdust Grinding Process: Hammer Mill Grinding Wood Chips Into Sawdust.

4. Sawdust Dying Process : Drum Dryer Dry Wet Sawdust into Dry Sawdust

(reduce 40-50% moisture content to 10-15%)

Package wood pellets into plastic bags or woven bags;

Package weight per bag: 1-5kg/bag; 1-10kg/bag; 5-25kg/bag; 15-50kg/bag;

| (1). What capacity would your prefer? -----The Capacity Range of Wood Pellet Machine: 0.5T/H; 0.8-1T/H; 1.5-2T/H; 2-3T;3-4T/H. |

| (2).What is your raw material? -----According to different raw material(such as hard wood,soft wood,straw,rice hust), capacity is different. |

| (3).What is your raw material size? -----Best size for pressing high quality pellets is 3mm-5mm. |

| (4).What is the moisture of your raw material? -----Better to be 10-15%.( If large than this, then we will recommend your Dryer Machine) |

| (5).Final Pellets Size? -----We have Diameter for Pellets:6mm, 8mm, 10mm, 12mm, (Different Diameters for your Different Requirement.) ------Pellets Length: Adjustable20-50mm. (Normally our clients ask pellets length of 33mm, between 30-36mm) |

4-10T/H wood pellet making line

Product Description

Production Flow Chart of Complete Wood Pellet Line:

Wood Chipping --- Sawdust Grinding ---- Drying ---- Pelletizing --- Cooling & Screening ---- Packing

| Introduction | Complete wood pellet line is the process of making waste materials into solid fuel. The objects are used for burning purposes. |

| Raw materials | Logs,Spruce, Pine, Birch, Oak ,Acacia etc Wood , Sawmill Waste Wood Planks, Furniture Factory Waste Wood, Sawdust, Bamboo, EFB, Nuts Shell etc. |

| Moisture and Size | 3-5mm; 10-15% moisture content |

| Diameter of wood pellets | 6/8/10/12mm |

Detailed Images

1. Wood Cutting Process : Chainsaw split big diameter wood into smaller one at first.

2. Wood Chipping Process: Wood Chipper Process Small Size Wood Into Wodd Chips.

3. Wood Sawdust Grinding Process: Hammer Mill Grinding Wood Chips Into Sawdust.

4. Sawdust Dying Process : Drum Dryer Dry Wet Sawdust into Dry Sawdust

(reduce 40-50% moisture content to 10-15%)

Package wood pellets into plastic bags or woven bags;

Package weight per bag: 1-5kg/bag; 1-10kg/bag; 5-25kg/bag; 15-50kg/bag;

| (1). What capacity would your prefer? -----The Capacity Range of Wood Pellet Machine: 0.5T/H; 0.8-1T/H; 1.5-2T/H; 2-3T;3-4T/H. |

| (2).What is your raw material? -----According to different raw material(such as hard wood,soft wood,straw,rice hust), capacity is different. |

| (3).What is your raw material size? -----Best size for pressing high quality pellets is 3mm-5mm. |

| (4).What is the moisture of your raw material? -----Better to be 10-15%.( If large than this, then we will recommend your Dryer Machine) |

| (5).Final Pellets Size? -----We have Diameter for Pellets:6mm, 8mm, 10mm, 12mm, (Different Diameters for your Different Requirement.) ------Pellets Length: Adjustable20-50mm. (Normally our clients ask pellets length of 33mm, between 30-36mm) |